Integrating your floor with the rest of your stage

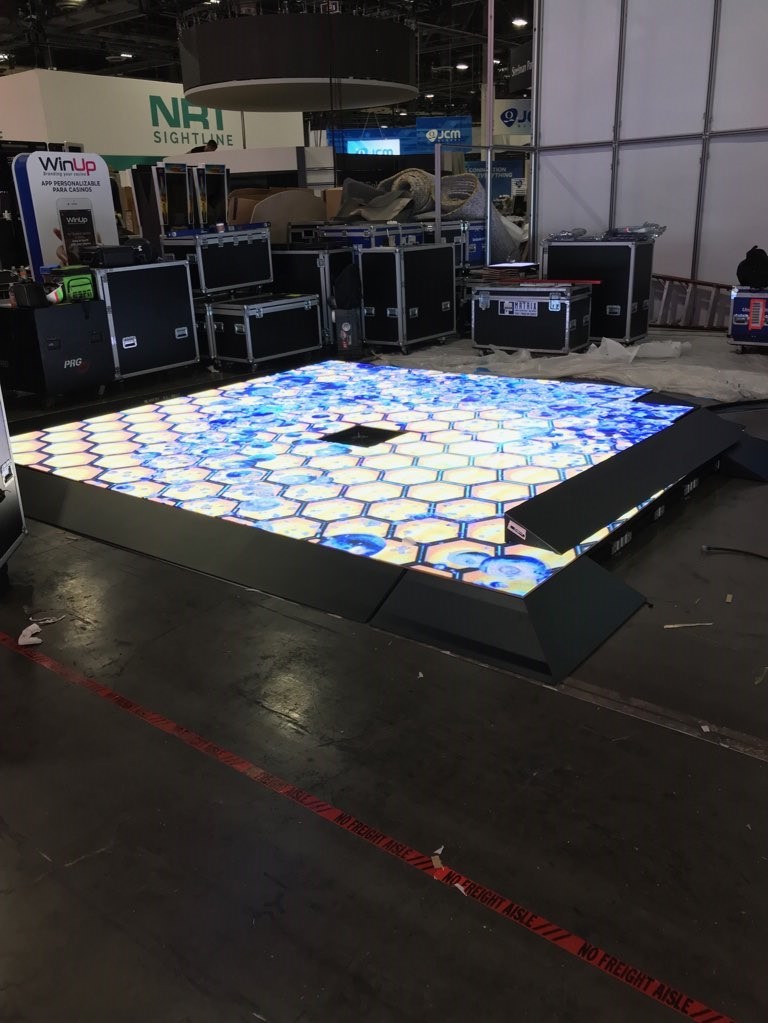

LED floor tiles are quickly becoming hot commodities. Their ability to create fully interactive floors, immersive tunnels and grand entrances is key in today’s world where experiential events matters ever more.

These tiles come in many shapes and forms, but the most difficult part about using them is actually to hide them!

Due to their size, laying the tiles flat on the ground means that you will either need to raise your entire stage by six inches, or risk a fall or injury by leaving them exposed.

What if you do not want someone to fall?

With so much on your mind already, the last thing you want is an injury. So what is the best way to solve the issue of raised LED panels?

One way to incorporate your LED floor with the rest of your stage is to use custom ramps. These not only prevent people from tripping or falling from the LED platform, but let you get creative with their design and drive vehicles on the floor.

These ramps, most often built by layering and shaping large segments of rubber, can be a good solution to a temporary problem; Indeed, building these ramps out of rubber means that they are very hard to re-use and usually require to be made all over again for the next show.

The Solution?

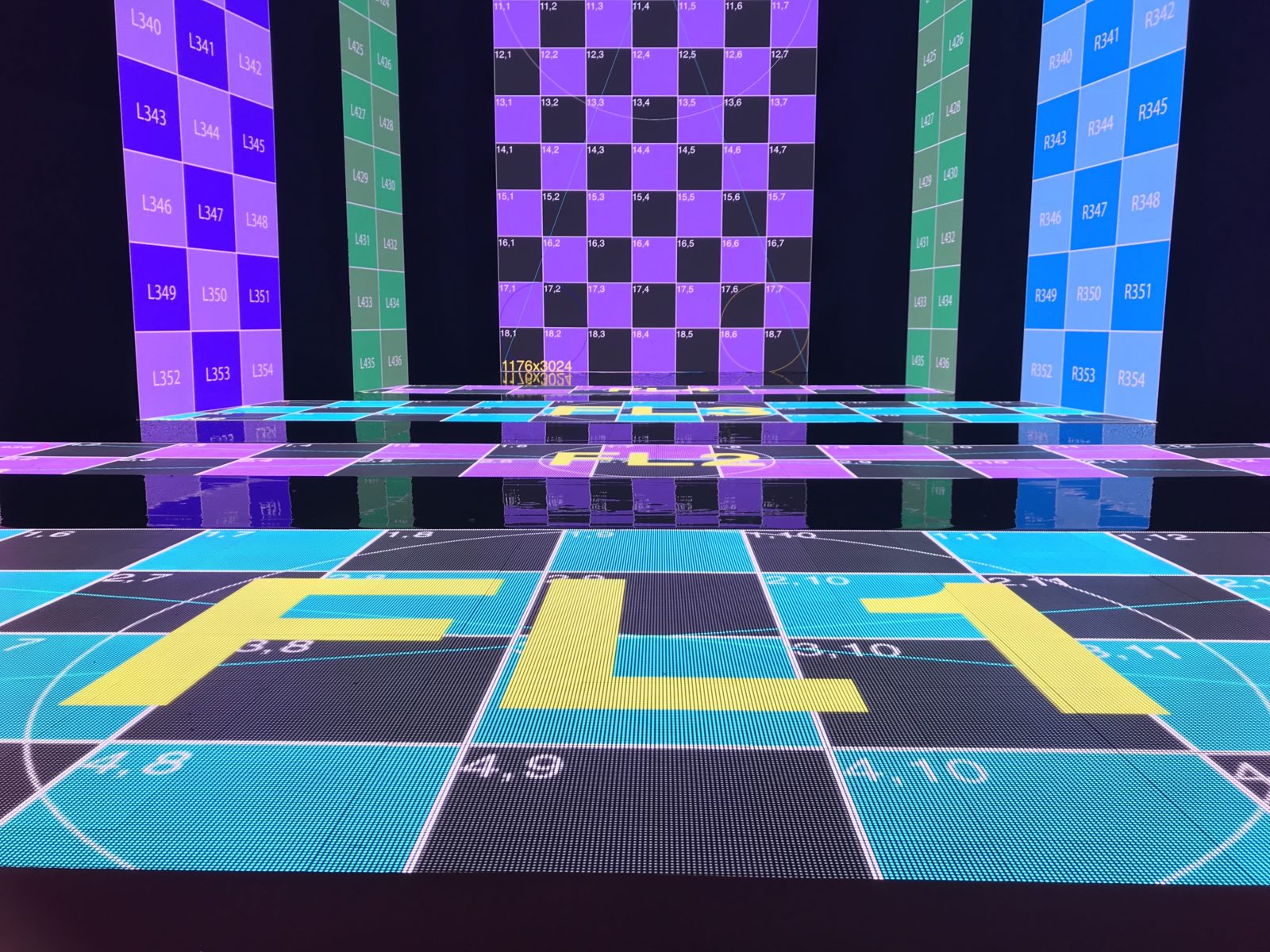

A more effective way to incorporate your LED floor might actually be to use steel. Steel is more durable than rubber, and as long as you have your corner pieces, it is only a matter of how many pieces you need for the length and the width.

Matrix Visual recently used steel ramps for its LED floors and it was a hit! For a company that works on live events across the country, it is essential to reduce uncertainties, and using steel ramps speeds up the pre-production process.

The need for LED floors is growing in the production industry, and the issue of integrating them with the rest of the stage cannot be ignored. While raising the entire stage is a solution, it is not always practical for companies that on the road most days of the year.

The versatility of small interlocking steel ramps might very well become the norm in the coming years and solve some of the structural issue of using LED floors.

For more articles on current and future trends in the LED world, subscribe below to our newsletter.