Chip on Board (COB) is a rather new technology in the LED panel world. New versions are introduced to the market this year, but while still an underdeveloped category, this new technology has been a big topic of conversation among LED professionals. In the end, the question still remains: Is COB the future technology we have been waiting for?

What is Chip On Board?

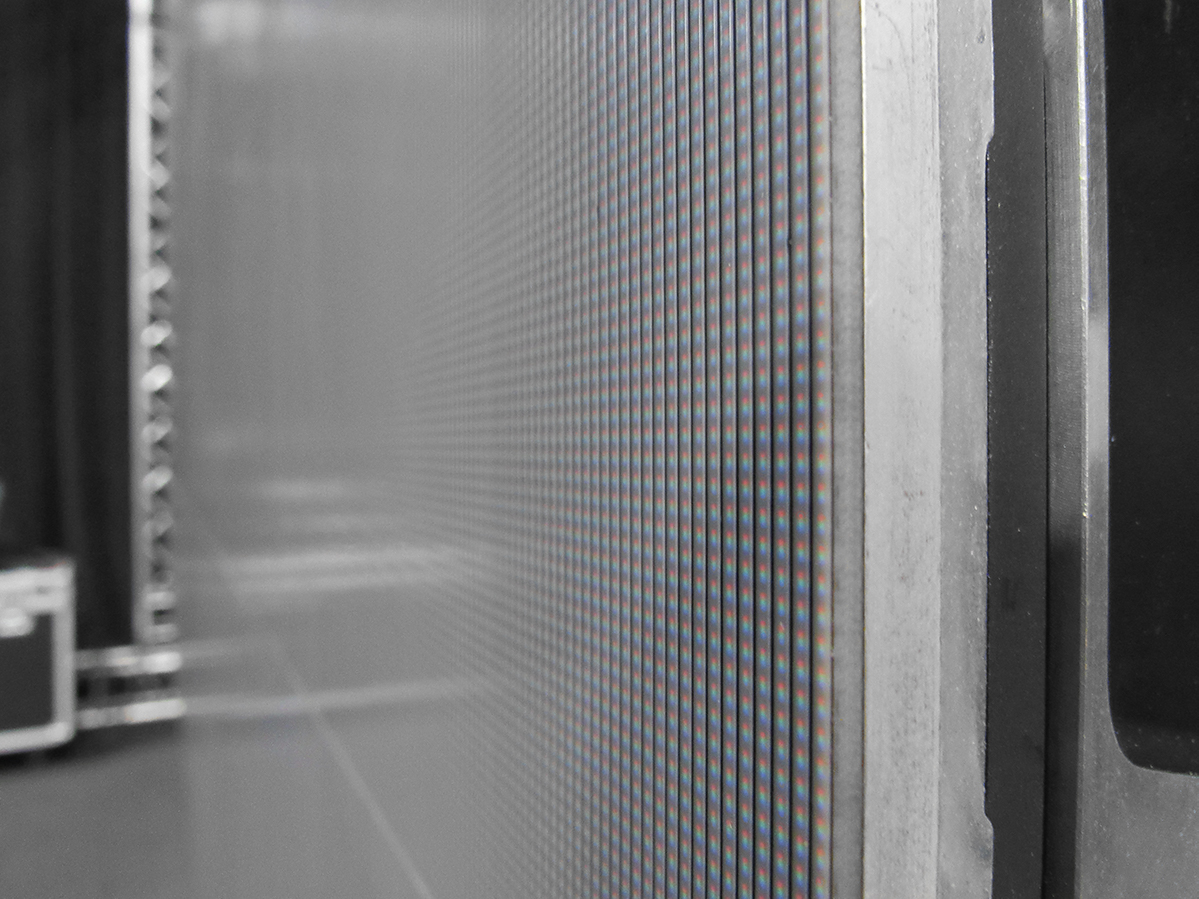

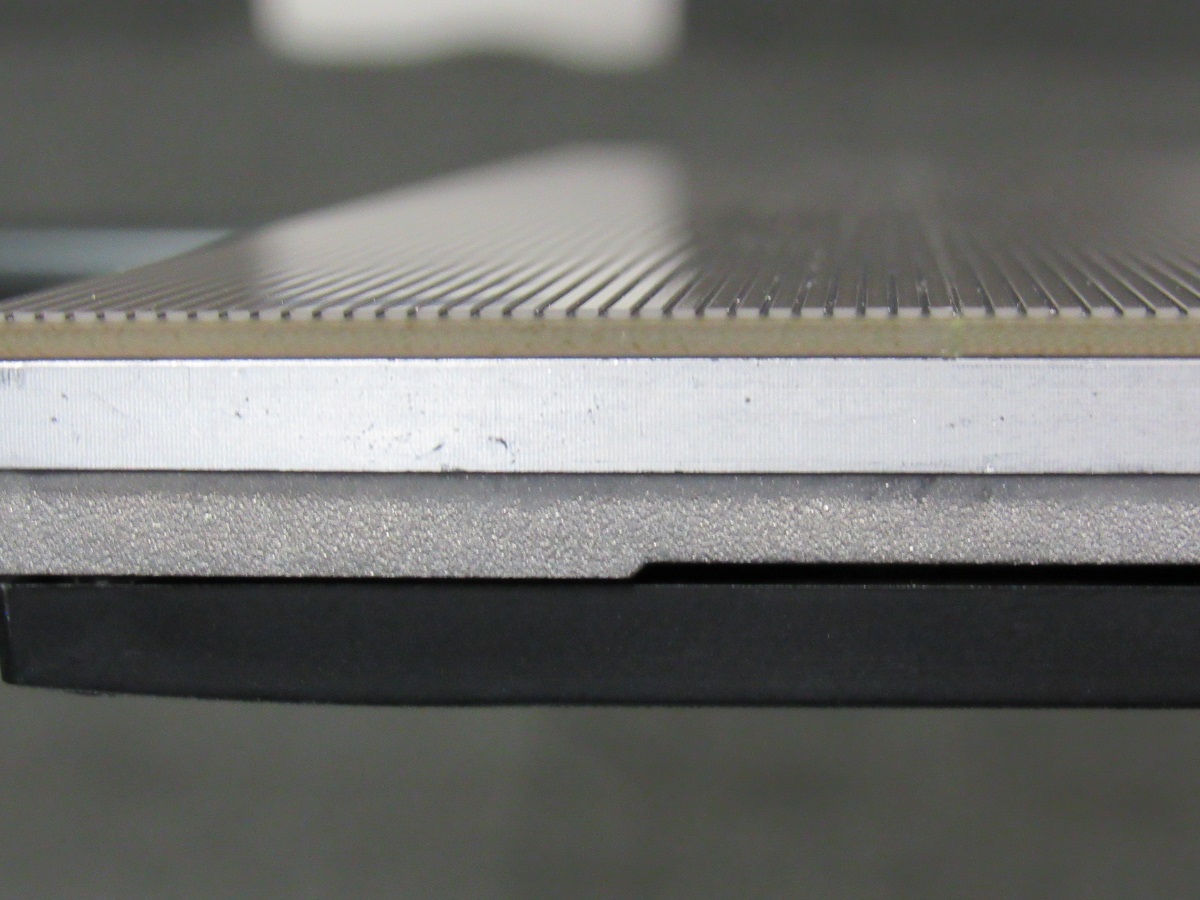

COB refers to the concept of embedding LEDs directly within the printed circuit board (PCB), an protecting them with a resin layer.

This method creates a very compact module where the smallest LEDs can be safely and effectively mounted while still being protected by the surrounding material. Unlike standard SMD (Surface Mount Device), COB LEDs are fully sealed and cannot be removed individually.

Why Chip on Board?

Every new technology is developed to fix an existing issue in the market. What COB is trying to achieve, is to protect the LEDs from damage, and particularly finding a way of protecting fine pixel LEDs that cannot be manually adjusted as they get smaller and smaller.

Advantage:

Being multi-chip packaged and mostly developed for fine pixel, COB LEDs have the advantage of concentrating a higher amount of light in a small space. This decreases light loss and increases the viewing angle. The greater viewing angle is the result of removing the usual packaging parts around the LED during the embedding process, and allows the fine LEDs to be closer together.

Another great advantage of COB LEDs is their durability and their ability to reduce repair time while on site. The resin packaging around the LED not only acts as a lens, but also protects the individual LEDs from physical damage. This added protection can have incredible results, and can protect the LEDs from physical forces 5x greater than with standard SMD LEDs. By condensing LEDs into one module, speedy on-site repair is also made much easier.

While the norm now is to use modules from spare panels to fix a failed module, COB LEDs allows an LED tech to only replace that specific module and not have to scavenge for one from spare panels. This becomes key when calculating shipping weight where shipping out spare modules instead of full LED panels saves lots of shipping weight, and take a lot less space to store when on-site.

Disadvantage:

COB LEDs have huge advantages over standard SMD LEDs, but one of their main limitation comes from their limited color spectrum.

Indeed not all types LED diodes can be encapsulated within the epoxy resin, and as the image gets more complex, the less crisp it will look since part of the light spectrum cannot be reproduced by the embedded LEDs.

Another disadvantage of COB LEDs is that while all the LEDs are protected within the epoxy resin, the moment one of them breaks down or gets damaged, the entire module needs to be changed, and individual LEDs cannot be repaired.

This is a consequence of the way the COB LEDs are built, and is unlikely to get fixed as more manufacturers experiment with this new technology.

Matrix Visual’s Experience with Chip on Board LED:

For the past two weeks, we have had the privilege of having a COB LED wall loaned to us, and after various experiments with multiple settings, images and videos, we are now ready to give you a quick breakdown of what we found:

The first element that we noticed, was just how difficult it was to push true black light through the panel, and also to have a perfectly black display when the panels are turned off. While we only tested one type of COB LED, and we cannot make a case for the entire technology, the wall we tested was not physically capable of producing enough black for a truly crisp image.

The gray colored epoxy protective layers had a huge effect on the ability to push out black, and the natural grayness of the product meant that no matter how hard we tried, it was not possible to have true black. When we asked our LED experts and our clients what suggestions they had to improve the technology, a common suggestion was to add a black film on top of the module, or add black pigments to the resin itself.

The second element we noticed was also just how easy it was to clean the panels and modules. A simple wet cloth cleaned everything, and since the LEDs are fully sealed and protected inside the epoxy resin module, there was no fear of damaging them.

Conclusion:

Our first thoughts regarding Chip on Board LED is that while it may still be in its infancy, the concept of COB LED sounds like it could be a winner. Our industry has been seeing pixels getting smaller and smaller, but there hasn’t been much innovation in the way the panels are manufactured.

LEDs are so delicate that almost 20% of all LED panels come back from show sites with some form of damage. Improving durability by sealing and protecting LEDs together can have huge benefits and possibly reduce the breaking rate that occurs on show site.

Overall, COB is not yet ready for the rental & staging world, but we were very excited to see that manufacturers are trying to overcome the real issues of the emerging LED market by tackling durability, ease of repair, weight, ease of built & above all, picture quality.

While we have not yet made a decision whether we want to add this new technology to our inventory, we really want to thank everyone who came to our showroom and gave us their insight on the COB LED wall.

Sources:

ProPhotonix:

Chip-on-Board LED

(www.prophotonix.com/resources/technical-overviews/chip-on-board-led/)

Digi-Keys Electronics:

The Basics of Chips on Board LEDs (www.digikey.com/en/articles/techzone/2016/aug/the-basics-of-chip-on-board-cob-leds)